Stop Using Outdated Metal Trim Techniques

Experience is a double-edged sword in construction. Many seasoned metal roofing contractors are still using trim installation methods from 20 years ago, simply because it’s how they learned to do it. The result? Dated metal trim practices are lingering on job sites, even as newer methods have proven far more effective.

Whether you’re installing metal roof trim at the eaves or metal siding trim on an outside corner, using proven, modern methods is key. In this post, we’ll call out an old trim method, why it’s a problem, and introduce the correct, modern metal trim installation based on weathertight warranty standards. The goal: help metal roof installers and contractors like you avoid pitfalls, deliver top-notch work, and build your reputation for quality.

Are You Still Installing Metal Trim Like This?

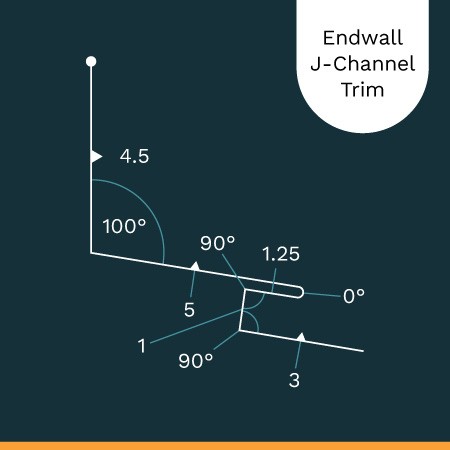

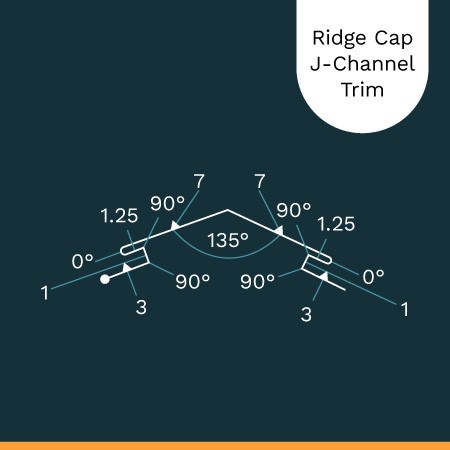

In the early 2000s, a common approach to finishing metal panel trim involved creative combinations of standard pieces. For example, some contractors would use a J-channel trim (often called J-metal) in tandem with other flashings, sliding panels into a J-channel at a roof-to-wall joint or under a ridge cap. This piecemeal technique aimed to save time and materials, but it often created a patchwork trim system. Critical transitions (such as where a metal roof panel trim meets a wall or ridge) were handled by nesting a J-channel with another flashing, then screwing everything together and relying on caulk or butyl to keep water out.

Why is this old J-metal approach no longer best practice? Put simply, it leaves too much room for error and water intrusion. For one, it usually involves exposed or poorly placed fasteners. In many old installations, contractors would run the roof panels up to the J-channel and screw through the panel and trim to hold it in place. This “quick fix” trim technique can literally punch holes in the very areas you’re trying to keep dry. As one expert notes, using a j-strip or z-strip screwed directly into the panels “punches the panels (i.e. leaks)” and even limits thermal movement. Over time, this means those screw penetrations and seams around the J-metal can become leak points, especially after sealants degrade. Water might wick behind the J-trim at an endwall or seep under a ridge cap that’s been cobbled together with J-metal. In short, yesterday’s trim tricks often turn into tomorrow’s leaks and callbacks.

Why the Old Method Is a Recipe for Leaks and Callbacks

Using an outdated trim method might save a few minutes today, but it sets you up for costly problems tomorrow. Here’s why this old approach falls short, especially in Montana’s extreme weather:

- Prone to Water Infiltration: Without proper overlapping metal-to-metal connections, wind-driven rain can work its way into seams. In fact, rain propelled by strong gusts can bypass standard roof defenses and lead to leaks, mold, and structural damage.

- Freeze-Thaw Cycle Damage: Any moisture that seeps in can freeze during Montana’s cold snaps. When water freezes, it expands, wedges gaps wider, and creates voids in the roofing/trim system. Then more water enters, freezes, and the cycle repeats. Over a winter of freeze-thaw cycles, a tiny leak can turn into a gaping problem. The [outdated trim detail] simply doesn’t have the layered protection to handle this natural abuse.

- Not Built for Heavy Snow: Some Montana mountain areas get up to 16 feet of snow annually. That means long periods of snow sitting against roofs and trim, slowly melting and continually testing every joint. Trim details with insufficient overlap or sealing is an open invitation for melting snow to creep in. Plus, snow and ice can put physical strain on poorly secured trim, pulling it loose or deforming it over time.

- No Backup if Sealant Fails: In modern weathertight construction, caulk and sealant are considered secondary barriers, extra insurance on top of proper flashing detail. In the outdated method, sealant is the primary defense. Once that caulk degrades (UV exposure, temperature swings, and time will do that), there’s nothing else to stop water. You’re left with leaks that could have been prevented by a better trim design.

Modern Solution: the “Weathertight Method”

It’s time to leave the jerry-rigged trim hacks in the past. The weathertight method for metal trim installation is a modern, specification-driven approach designed to eliminate the weak links of old practices. This method is rooted in the requirements of weathertight warranties, rigorous warranty programs (typically for commercial metal roofs) that dictate exact installation details for every trim and flashing.

Under a weathertight warranty, the manufacturer and installer guarantee the roof won’t leak, so they insist that trim is installed“to the proven standards and details specified and approved by the metal roof manufacturer. In practice, even if you aren’t pursuing a formal warranty, following these warranty-level specs is the smartest way to install metal roofing trim.

What Does the Weathertight Method Look Like on the Roof?

It starts with using purpose-made trim components for each condition (endwalls, sidewalls, ridges, hips, corners, etc.) rather than mixing and matching pieces. Each trim is installed with careful attention to layering and sealant. Key elements of a weathertight trim installation include:

- Underlaps & Overlaps: Trim sections are properly overlapped by the required amount (often 6” or more) and secured, with sealant at all overlaps to prevent capillary action. No more simply butting two pieces under a J-channel; every joint is designed to shed water.

- Butyl Tape & Sealants: Wherever a trim piece interfaces with panels or another flashing, butyl tape or sealant is used in the correct locations. For instance, modern specs call for double-sided butyl tape under endwall flashing and bead sealant atop closure strips. These continuous sealant layers block wind-driven water.

- Closure Strips and Gaskets: Rather than relying on a J-metal channel to catch water, the weathertight method uses foam closure strips and profile gaskets to fill gaps under trim. At a ridge, for example, foam closures are placed along the panel ribs before the ridge cap goes on. This ensures the ridge is sealed against infiltrating rain or snow, a big upgrade from older methods that left open voids.

- Strategic Fastening (No Unnecessary Holes): Fasteners are placed where they won’t leak or impede movement. With weathertight details, you typically avoid screwing through flat pan sections of panels in critical areas. Instead, screws might go through raised ribs or into ancillary pieces designed for that purpose. Panel expansion/contraction is accounted for, preventing stress cracks or loosened screws.

- Precision and Verification: Installers often follow official detail drawings for trim installation, and work may be inspected or tested for leaks on warranty jobs. It’s a far cry from “winging it” with whatever trim you have on hand. The payoff is a roof that’s as close to impermeable as possible.

By embracing these techniques, you’re building roofs to meet or exceed warranty-grade standards. Even if a project doesn’t require a formal warranty, using the weathertight method means you’re treating the roof as if it did, which is a mark of quality and professionalism.

Montana Weather Makes Weathertight Trim a Must

Montana’s extreme climate—from fierce winds and heavy snow to ice damming and frequent freeze-thaw cycles—puts tremendous stress on metal roof trim. These conditions make it essential to use the most up-to-date, weathertight metal trim installation techniques and standards to prevent leaks and damage. Modern trim practices ensure every edge is properly sealed against wind-driven moisture and the expansion of ice, so roofs can withstand Montana’s harsh seasons without the failures that come from outdated methods.

Benefits of Adopting Weathertight Trim Installation

- Fewer Callbacks & Leaks: A trim installed with proper closures, sealants, and overlaps is far less likely to let water through. That means no more frantic phone calls from clients when the next rainstorm hits. In the long run, you save time and money by avoiding warranty repairs or reputation-damaging failures.

- Better Roof Performance: Weathertight trim means the entire roofing system performs as intended. Issues like rusting fasteners, loose metal corner trim, or hidden rot are minimized. The roof lasts longer and maintains its integrity, which keeps your clients happy.

- Longer Lifespan & Less Damage: By preventing moisture infiltration at joints, you also prevent the secondary damage it causes (rust, mold, insulation damage, etc.). A roof built with high standards for trim will age more gracefully. It’s not uncommon for roofs installed to weathertight specs to far outlast those with shortcut methods, giving building owners more value from their investment.

- Alignment with Best Practices & Specs: Adopting the weathertight approach puts you in line with the latest industry best practices. You’ll be meeting the standards that architects and manufacturers call for in new commercial projects, which can future-proof your craft by staying current.

Weathertight Standards at GNMC, Even Without a Warranty

At Great Northern Metal Company, we firmly believe that every project deserves the highest standards. Whether or not the end customer has purchased a formal weathertight warranty, our philosophy is to apply those same weathertight installation principles on every job. Why? Because it’s simply the right way to build. We know that if a trim detail wouldn’t pass muster for a warranty, it’s not going to be acceptable for Montana’s climate in the long run.

What Does This Mean for You as a Contractor?

When you work with Great Northern Metal Company, you can trust that weathertightness is baked into everything we do. Our trim products are designed for proper overlaps and easy sealing. Our team can provide guidance or even customized trim solutions to tackle tough conditions (odd roof junctions, high-snow areas, etc.) with no compromise on durability.

We don’t cut corners on “hidden” details. For example, if you order a custom metal corner trim from us for a siding project, we’ll ensure it’s designed to integrate with closures or sealant as needed, just like a warrantied system. Even if your client opted not to pay for a manufacturer’s warranty, they still get the benefit of those best practices. The result is fewer leaks and callbacks for you, and a better reputation for everyone involved.

Great Northern Metal Company has built its name on quality and expertise. We’re not the kind of supplier who just hands you some stock trim and sends you on your way. We want to make sure your installation goes smoothly and performs exceptionally.

Ready to Avoid Headaches? Contact GNMC for Custom Trim Guidance

Don’t settle for outdated methods that put your work at risk. There’s a better way, and Great Northern Metal Company is here to help you implement it. If you’re unsure whether your current trim approach is up to par or want advice on a tricky detail, reach out to our experts. We’re happy to provide guidance, recommend the right solution, or even craft custom metal trim pieces to fit your project’s needs.

Contact Great Northern Metal Company for project consultations, technical support, or custom trim fabrication that meets the highest standards.