Fastening metal roof panels, especially exposed fastener panels, seems like a straightforward process. But common mistakes can lead to big problems down the line, leading to complaints and repair calls from your customers. That’s why our team always emphasizes the importance of following the exposed fastener installation guides for your chosen metal panels; they’re your roadmaps for successful metal panel installation.

Getting the basics right when installing exposed metal roof panels ensures a secure, durable, and weather-resistant roof. In a state like Montana, having a reliable roof can mean the difference between a cozy, comfortable home and a miserable winter season (which can last into June some years!).

We know as well as anyone that it’s easy to make mistakes, but we want to save you the headache and time in the long run. So you can protect your customers, your team, and your reputation in the Montana roofing industry, avoid these critical errors that could compromise the effectiveness of your exposed metal roofing panels.

Avoid These 5 Mistakes When Fastening Exposed Fastener Panels

Mistake 1: Not Knowing Where to Put the Screws

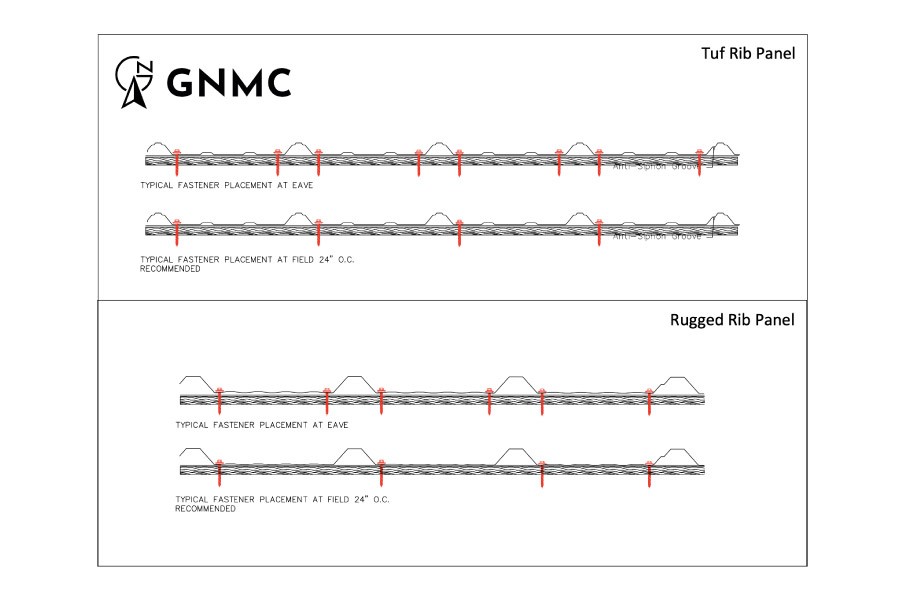

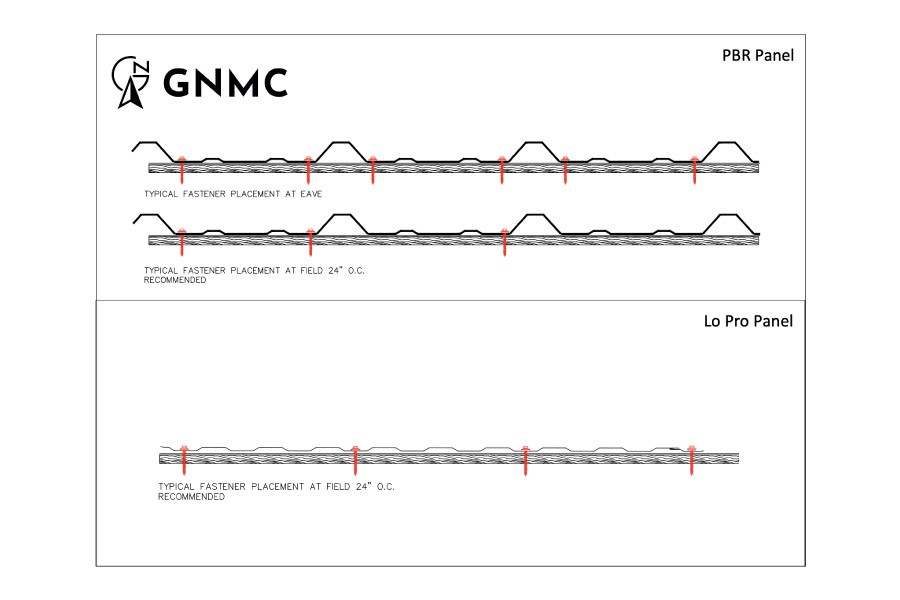

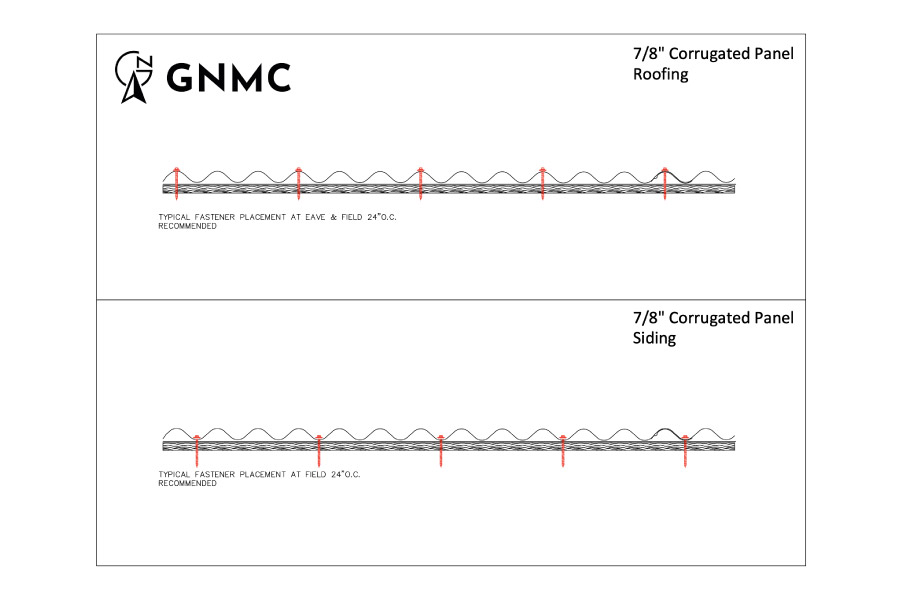

One of the most common mistakes when fastening exposed fastener metal roof panels is not knowing the optimal places for screw placement. Depending on the type of panel you are using, or whether you are placing a screw at the field or eave, this can mean major differences in where you place your screws.

For example, with corrugated panels, you may be placing a screw in the valley (the lowest point or trough) of a corrugation in one case and, in the next, at the peak (the highest point or ridge) of a corrugation. It all depends on your chosen panel, whether you are installing at the eave or field, and what the installation guide instructs. That’s why we highly recommend always reviewing the panel installation guides before fastening any panels.

Mistake 2: Over or Under Tightening Screws

The tightness of your screws is pivotal—literally! Too tight and you risk stripping the screw hole or deforming the metal panel and making the neoprene washer nonfunctional. Too loose and you may find your roof vulnerable to wind uplift or water ingress. Use a torque-controlled drill or driver to ensure consistent settings that match the manufacturer’s specifications and installation guides for optimal installation.

Mistake 3: Not Pre-drilling Panels

Failing to pre-drill panels before fastening panels can lead to misalignment, damaged panels, and extra strain on screws. Pre-drilling helps ensure that screws go in cleanly and evenly, reducing the risk of damaging both the screw and the panel, and it facilitates correct alignment across the roof. Plus, pre-drilling makes panels look aesthetically pleasing, so clients will thank you for pre-drilling your panels.

Before you drill your panel holes, double-check that you have selected the correct drill bit. Remember a simplerule of thumb: a smaller fastener means a smaller drill bit.

Mistake 4: Choosing the Wrong Screw

Various screws are suited to different types of metal roofing, and using the wrong kind can lead to corrosion, leaks, and structural failure. Always choose screws that are specifically designed for metal roofing, preferably with a sealant (neoprene) washer to ensure a waterproof seal at the penetration point.

Each type of screw has tested engineering data for “pull out” values, or the amount of force required to pull a screw out from the material it’s fastened into. This value is critical because it measures the screw’s ability to provide a secure and durable hold in various substrates, such as wood, metal purlins, or dense insulation boards that are part of the roofing system. Always choose your screws based on the location of the screw, installation guide recommendations, weather conditions, and diameter. Because metal expands and contracts, you want to make sure you use the correctscrew so it stands the test of time.

Mistake 5: Mis-aligned Screws

A screw that goes in crooked can compromise the seal and hold of the screw. To avoid this, take the time to ensure that each screw is perpendicular to the panel as you drive it in. This prevents uneven surfaces and ensures that the stress on the screw and the panel is evenly distributed.

Have More Questions? We’ve Got Your Back!

Need more tips on installing metal roof panels? Looking for industry experts’ advice on choosing supplies and metal roof panels? Look no further than the Great Northern Metal Company team! We’re always happy to lend a hand so your project is the best it can be. Contact us today, and let’s make sure your roofing project is a success from start to finish.